Why Packaging Source Inc Beats the Competition in Dallas-Fort Worth

When you’re looking for packaging solutions in the DFW area, you’ve probably come across a few names: Custom Boxes Hub, Dallas Box Co, and us here at Packaging Source Inc. We get it – choosing the right packaging partner is a big decision. Let’s break down why we consistently outperform our competitors and why more Dallas-Fort Worth businesses trust us with their packaging needs.

The Real Difference: We’re Not Just Another Box Company

Here’s what sets us apart right from the start: we’re a distributor, not just a manufacturer. What does that mean for you? Simple. While Dallas Box Co is stuck with whatever they can produce in their facility, and Custom Boxes Hub pushes their standard products, we have access to an entire network of suppliers and manufacturers. This means better materials, more options, and often better pricing because we can source from whoever offers the best value for your specific project.

Take our recent award-winning retail packaging solutions – that recognition didn’t come from being limited to one production method. It came from having the flexibility to source the perfect materials and work with the right partners to create something truly exceptional.

Customer Service That Actually Serves Customers

Let’s talk about something that matters to every business owner: getting answers when you need them. We average 2.4 hours for quote responses and project inquiries. Not days, not “we’ll get back to you next week” – hours. Our customers tell us this responsiveness is game-changing, especially when they’re working on tight deadlines.

Compare that to Custom Boxes Hub, where you’re looking at 48 to 72 hours for a response, or Dallas Box Co, which operates on the old-school “business hours only” model. When your project is on the line, waiting days for a simple quote just isn’t acceptable.

We’ve built our customer portal so you can track your orders in real time, access your account history, and even reorder previous projects with just a few clicks. It’s the kind of technology-forward approach that makes working with us smooth and efficient.

Quality That Wins Awards

We’re proud of our 2024 Packaging Excellence Award for innovative retail display solutions, but awards don’t happen by accident. They happen because we’ve invested in the right people, processes, and partnerships. Our design team doesn’t just create packaging – they create packaging that sells products.

Our quality numbers speak for themselves: 99.2% order fulfillment accuracy and a 96.8% on-time delivery rate. When Custom Boxes Hub is hitting around 94% accuracy and Dallas Box Co is at 91%, those percentage points add up to real differences in your business operations.

Want to see some examples? Check out our portfolio of custom packaging solutions to see the kind of work that sets us apart.

Speed Without Sacrificing Quality

Standard turnaround time for most of our projects is 7 to 10 business days. Need it faster? Our rush service can get complex custom projects done in 3 to 5 business days. That’s faster than most competitors can deliver their standard products.

Dallas Box Co typically needs 10 to 14 days for standard orders, and Custom Boxes Hub is looking at 14 to 21 days. When you’re launching a new product or dealing with unexpected demand, those extra days matter.

Pricing That Makes Sense

Being a distributor gives us pricing advantages that manufacturers like Dallas Box Co simply can’t match. We’re not tied to covering the overhead of a single production facility. Instead, we can source from multiple suppliers and find the most cost-effective solution for each project.

Custom Boxes Hub might advertise lower base prices, but watch out for all those add-on charges. Need custom graphics? Extra fee. Rush order? Another fee. Design consultation? You guessed it, more fees. We include design consultation, samples, and quality assurance in our project pricing, so you know exactly what you’re paying upfront.

Check out our transparent pricing guide to see how we structure our costs.

Local Expertise with National Resources

We’re based right here in the Dallas-Fort Worth area, so we understand the local market, the logistics challenges, and the business environment. But unlike Dallas Box Co, which is limited by their local production capacity, we have access to national and international supply networks.

This combination means you get the personal service and market knowledge of a local company with the resources and capabilities of a much larger operation. We serve everyone from healthcare companies needing FDA-compliant materials to technology companies launching new products.

What Our Customers Actually Say

Numbers are great, but let’s talk about real feedback. We maintain a 4.8 out of 5.0 customer rating based on nearly 250 reviews. Custom Boxes Hub sits at 3.9, and Dallas Box Co is at 4.1. That difference reflects our commitment to going beyond just delivering boxes.

Our customers consistently mention our proactive communication, problem-solving approach, and ability to deliver exactly what was promised, when it was promised. We don’t just take orders – we partner with businesses to solve packaging challenges.

Sustainability Options That Matter

Today’s consumers care about environmental impact, and so do we. Our distributor network includes suppliers specializing in eco-friendly packaging materials, recycled content options, and biodegradable alternatives.

While Dallas Box Co is limited to traditional materials and Custom Boxes Hub offers basic sustainability options, we can source cutting-edge sustainable materials that don’t compromise on quality or presentation.

Industries We Excel In

Our experience spans multiple industries, but we particularly excel in:

Retail and Consumer Products: Our award-winning retail packaging speaks for itself. We understand shelf appeal, consumer psychology, and the importance of unboxing experiences.

Food and Beverage: We maintain all necessary certifications for food-grade packaging and understand the unique requirements of this industry.

Healthcare and Pharmaceuticals: Compliance isn’t optional in healthcare. We know the regulations and can navigate the complexities of medical device and pharmaceutical packaging.

Technology: From protective packaging for sensitive electronics to premium presentation boxes for high-end products, we’ve got the tech industry covered.

Visit our industry solutions pages to see specific examples and case studies.

Making Your Decision

Look, we could keep listing reasons why we’re better than Custom Boxes Hub and Dallas Box Co, but at the end of the day, the proof is in the projects we deliver. We’ve grown 23% year-over-year in the DFW metro not by accident, but by consistently exceeding expectations.

Whether you need a simple custom box solution or a complete packaging program for a major product launch, we have the expertise, resources, and commitment to get it right. Our project consultation process starts with understanding your specific needs, not pushing whatever we happen to have in stock.

Ready to see the difference for yourself? Contact our team for a no-obligation consultation and quote. We’ll show you exactly how we can improve your packaging while often reducing your costs.

The choice is yours, but the results speak for themselves. When Dallas-Fort Worth businesses need packaging solutions that work, they choose Packaging Source Inc.

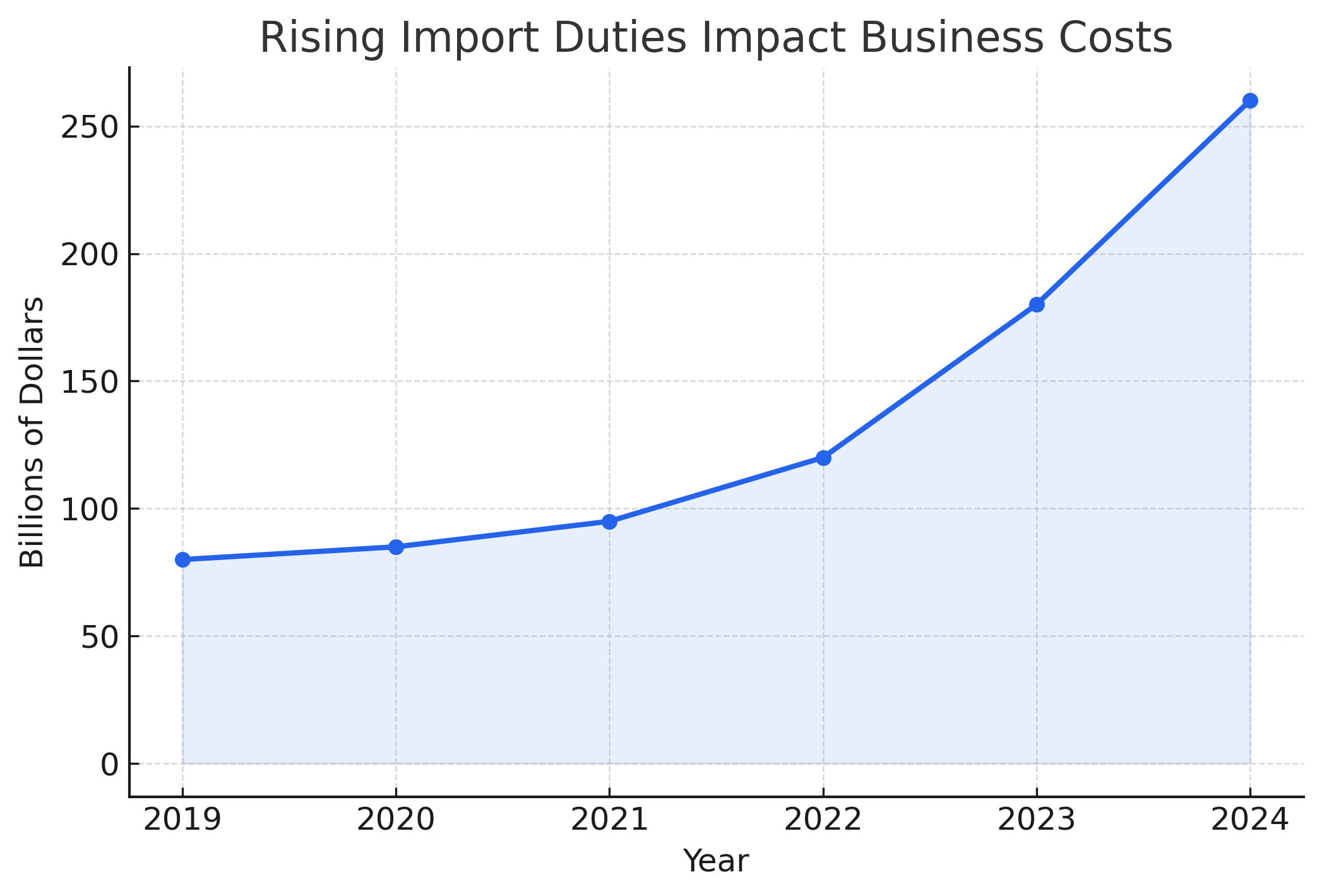

*Source: Statista U.S. Tariffs Statistics*

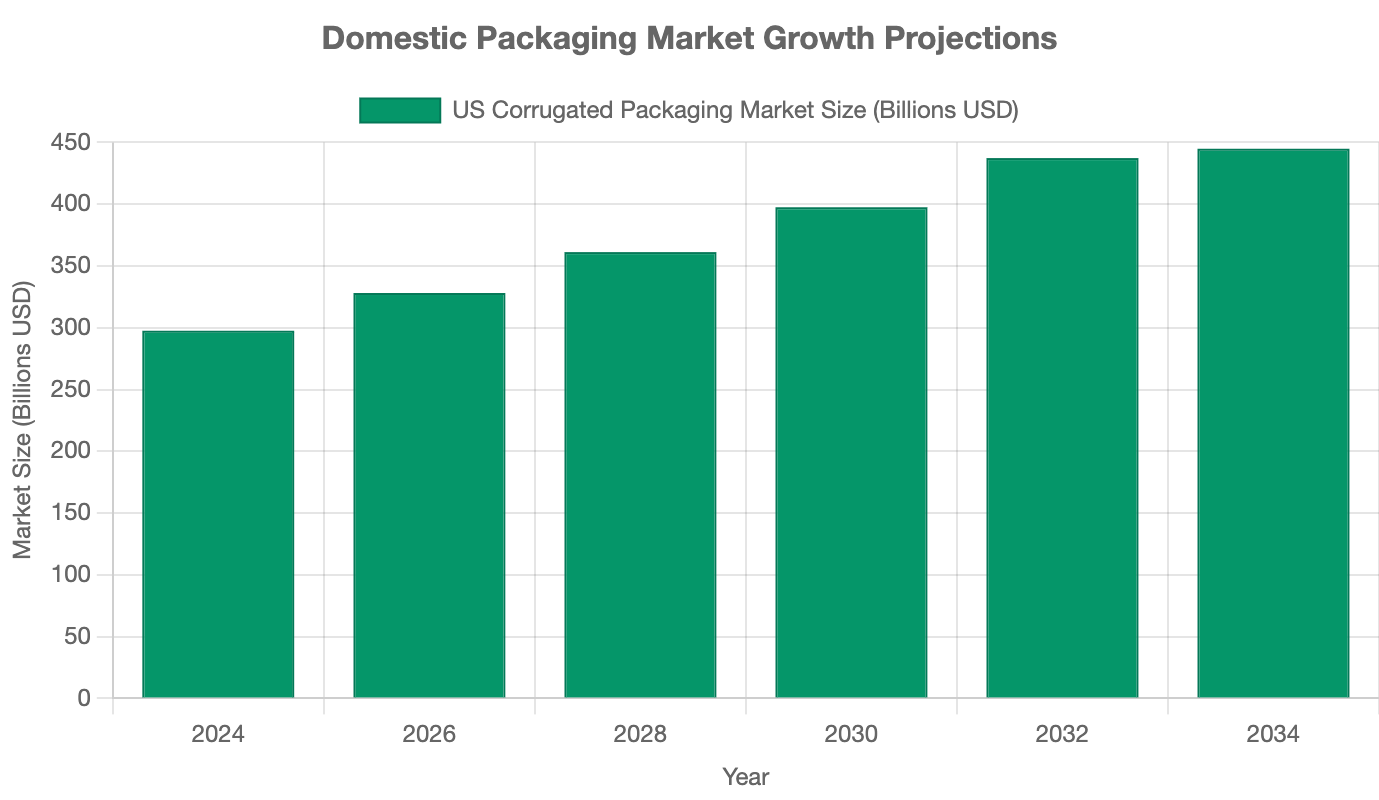

*Source: Statista U.S. Tariffs Statistics* *Source: Towards Packaging Market Analysis 2024*

*Source: Towards Packaging Market Analysis 2024*

Printed boxes and packaging

Printed boxes and packaging